Advantages of Using High-Quality Starter Hoses in Aviation

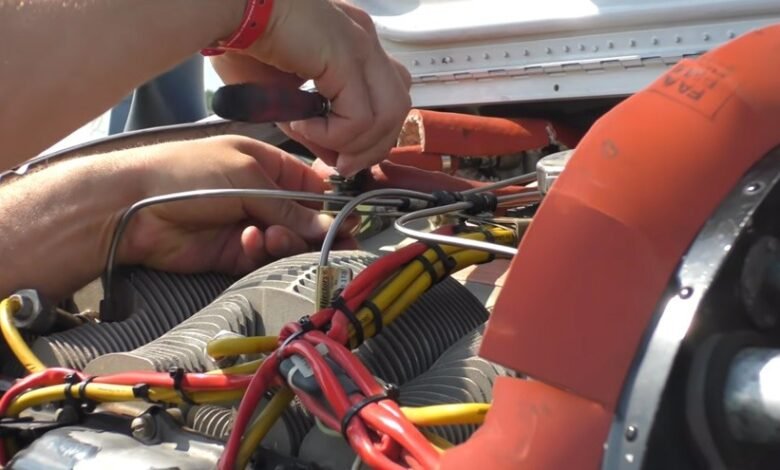

In aviation, the materials must be of high quality to improve safety and performance, but many do not consider the starter hose. These hoses link the ground power units to a plane’s engine to supply the same airflow and pressure as required for starting the engine. Choosing the right types of initial hoses as well also contributes to the maximum efficiency of an engine as well as increases the level of reliability and security of the plane’s operation. These are the benefits of using high-quality starter hoses for airlines.

1. Durability and Longevity

Initial hoses are designed and developed to withstand the various harsh conditions found in aviation applications. Made from high-quality materials that do not wear off, rust, or melt under high temperatures, these hoses are designed to stay functional for long, all under complicated working conditions. Conversely, hoses of a lower quality deteriorate quickly again means more replacements and more probability of failures during important engine starts.

Choosing high-quality and long-lasting hoses, also reduces the need to spend time with maintenance work, avoids possible costly breaks or other breakdowns, and overall decreases the chance of having an accident due to equipment failure. This eventually leads to efficiency and improvement of the flight safety systems throughout the airline industry.

See also: Key Benefits of Short Code Texting for Instant Communication

2. Enhanced Safety

The starter hose is responsible for carrying cleaned and filtered air into the engine, and for a smooth engine start, it has to be in perfect working order. Because low-quality hoses leak, crack, or burst when under pressure, they can greatly damage the aircraft or pose safety risks. At times, a malfunction in the starter hose may lead to engine failure or some other hitch that may be dangerous to flight safety.

Starter hoses, on the other hand, should be made using high-quality and durable material to ensure that the pressure and airflow are standardized, which also helps cut out on failure. Through proper procurement of hoses, aviation professionals are assured of a safe environment, and more so, the aircraft won’t be affected, thereby reducing cases of operations being interrupted due to a breakdown.

3. Improved Performance and Efficiency

The reliability of your power and airflow during engine start-up is critical when it comes to engine performance. Starter hoses with high quality are always smooth because they always start gradually. The advantages include the time which is not taken to start the engine and also the aircraft is ready to be flown. Fuel savings, lower engine wear over time, and better overall performance and operational efficiency for the aircraft all grow out of efficient engine starts. A jet starter hose made of a reliable material guarantees that at the time of starting up, optimal airflow and pressure remain. In addition to getting the starting engine to get going quicker, this also extends the life of the engine and lowers the need for routine repairs and maintenance.

4. Compatibility and Versatility

They make a high-quality starter hose suitable for being used with a wide range of aircraft types and ground power units. This versatility lets ground crew use one hose for many aircraft, cutting down on needing to carry a separate hose for every different aircraft type. No matter what the aircraft’s engine’s model or make, with the right hose, you can be assured that the power and airflow requirements will be met.

This compatibility is necessary to smooth the ground support operations and to have the equipment used in the ground support process effective and efficient. Further, a single high-quality hose across multiple aircraft types represents another way to lower maintenance costs while reducing inventory management by virtue of fewer specialized hoses needed.

Conclusion

Utilizing high-quality starter hoses in aviation is advantageous, compounding the conception that reduced costs are usually associated with disadvantaged products. These hoses are very important for normal and safe start-ups of the engines in line, making important contributions to flight operations. The material quality, compatibility, and performance of this initial hose have to be given much importance when choosing one. It has been found that the use of dependable hoses with high performance boosts safety, cuts down on spare time, and drives up the effectiveness of aircraft use. High-performance hoses minimize interruptions and increment airplane productivity.